Fostering a skilled workforce for future operational demands

The rapid evolution of global markets and technological advancement has fundamentally reshaped how enterprises approach workforce development. Organizations across manufacturing, logistics, and production sectors now face the critical challenge of building teams equipped with capabilities that extend beyond traditional skill sets. Addressing this need requires strategic integration of training programs, digital tools, and sustainable practices that prepare employees for increasingly complex operational environments while maintaining competitive advantage in dynamic markets.

Modern enterprises recognize that human capital remains their most valuable asset, particularly as automation and digitalization transform traditional workflows. Building a workforce capable of meeting future operational demands involves comprehensive strategies that balance technical proficiency with adaptability. Organizations must invest in continuous learning frameworks that evolve alongside technological innovation, ensuring employees develop competencies aligned with emerging industry requirements.

How Does Manufacturing Transformation Impact Workforce Needs?

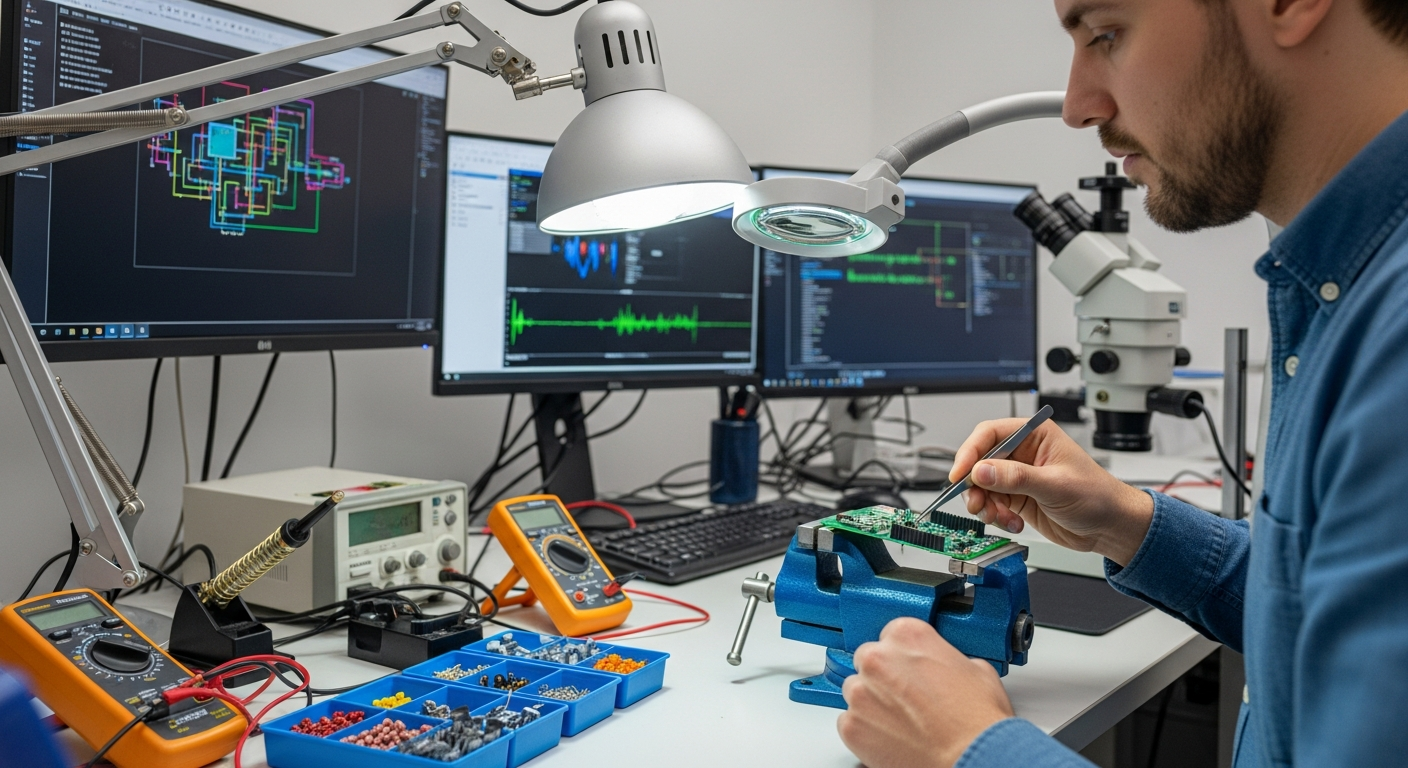

Manufacturing environments have undergone significant changes driven by advanced robotics, artificial intelligence, and data analytics. Workers now require proficiency in operating sophisticated machinery, interpreting complex datasets, and collaborating with automated systems. Traditional assembly line roles have expanded to include responsibilities such as predictive maintenance, quality control through digital monitoring, and process optimization. Companies that prioritize upskilling initiatives create environments where employees transition smoothly from legacy systems to modern production platforms. This transformation demands investment in technical training programs, mentorship opportunities, and hands-on experience with emerging technologies that define contemporary manufacturing landscapes.

What Role Does Technology Play in Operations Excellence?

Technology serves as the backbone of efficient operations across industries. Cloud-based management systems, Internet of Things sensors, and machine learning algorithms enable real-time visibility into production cycles, inventory levels, and supply chain movements. Employees must understand how to leverage these tools to identify bottlenecks, reduce waste, and enhance productivity. Organizations benefit from establishing digital literacy programs that demystify complex platforms and encourage experimentation with new solutions. As technology continues advancing, workforce development strategies should emphasize continuous learning rather than one-time training sessions, fostering cultures where adaptation becomes second nature.

Why Is Supply Chain Resilience Critical for Growth?

Global disruptions have highlighted vulnerabilities within interconnected supply chain networks. Building resilience requires teams skilled in risk assessment, contingency planning, and agile response mechanisms. Logistics professionals must navigate fluctuating demand patterns, transportation challenges, and regulatory variations across markets. Training programs focused on scenario planning, data-driven decision-making, and cross-functional collaboration strengthen organizational capacity to withstand unexpected disruptions. Companies investing in supply chain education create competitive advantages through faster recovery times, reduced operational costs, and improved customer satisfaction during challenging periods.

How Can Automation Enhance Workforce Productivity?

Automation eliminates repetitive tasks, allowing employees to focus on strategic activities requiring human judgment and creativity. Rather than replacing workers, well-implemented automation augments capabilities and creates opportunities for higher-value contributions. Successful integration requires transparent communication about technology’s role, comprehensive training on new systems, and clear pathways for career advancement within automated environments. Organizations should design workflows that complement human strengths such as problem-solving, innovation, and relationship management while delegating routine processes to machines. This balanced approach maximizes efficiency gains while maintaining employee engagement and satisfaction.

What Strategies Drive Innovation and Enterprise Growth?

Innovation thrives in environments that encourage experimentation, reward creative problem-solving, and provide resources for testing new approaches. Enterprise growth depends on workforce members who can identify market opportunities, develop novel solutions, and execute strategic initiatives effectively. Organizations should establish innovation frameworks that include dedicated time for exploration, cross-departmental collaboration, and mechanisms for capturing employee insights. Leadership plays a crucial role in modeling innovative behaviors and creating psychological safety where calculated risks are supported rather than penalized. Companies fostering innovation cultures position themselves to capitalize on emerging trends and maintain relevance in evolving markets.

How Does Sustainability Integrate with Workforce Development?

Sustainability has become a strategic priority influencing operational decisions across industries. Employees need understanding of environmental impact assessments, resource optimization techniques, and circular economy principles. Training programs incorporating sustainability concepts prepare teams to identify efficiency improvements that simultaneously reduce costs and environmental footprints. Green manufacturing practices, waste reduction initiatives, and energy-efficient logistics operations require specialized knowledge that organizations must systematically develop within their workforce. As regulatory requirements and consumer expectations around sustainability intensify, companies with environmentally literate teams gain competitive advantages through compliance readiness and market differentiation.

What Management Approaches Support Digital Transformation?

Digital transformation extends beyond technology adoption to encompass cultural shifts in how organizations operate and make decisions. Management must champion data-driven approaches while maintaining focus on human elements that drive engagement and performance. Effective leaders balance investment in digital infrastructure with attention to change management, ensuring employees understand transformation objectives and feel supported throughout transitions. Transparent communication about digitalization goals, regular feedback mechanisms, and recognition of adaptation efforts create environments where workforce members embrace rather than resist technological evolution. Organizations succeeding in digital transformation view it as an ongoing journey requiring continuous investment in both systems and people.

Building a workforce prepared for future operational demands requires holistic strategies addressing technical skills, adaptive capabilities, and strategic thinking. Organizations that invest comprehensively in employee development create sustainable competitive advantages through enhanced productivity, innovation capacity, and operational resilience. As markets continue evolving and technology advances, the distinction between successful and struggling enterprises will increasingly depend on workforce quality and organizational commitment to continuous learning.