The role of data in industrial management

In today's rapidly evolving industrial landscape, data has emerged as a cornerstone for informed decision-making and operational excellence. From optimizing complex processes to predicting market trends, the strategic utilization of data is reshaping how businesses operate across various sectors. Understanding its multifaceted role is crucial for organizations aiming to enhance efficiency, drive innovation, and maintain a competitive edge in a globalized economy.

Data-Driven Operations and Manufacturing Efficiency

Data plays a pivotal role in refining industrial operations and boosting manufacturing efficiency. By collecting and analyzing real-time data from production lines, machinery, and sensors, businesses can gain deep insights into performance bottlenecks, equipment health, and quality control. This allows for proactive maintenance, minimizing downtime, and optimizing resource allocation. Precise data analysis helps identify patterns and deviations, enabling managers to fine-tune processes for maximum production output and reduced waste.

Implementing data analytics in operations can lead to significant improvements in overall productivity. For instance, predictive analytics can forecast equipment failures before they occur, scheduling maintenance during non-peak hours and preventing costly disruptions. This data-centric approach transforms reactive problem-solving into proactive strategic planning, ensuring smoother workflows and consistent product quality.

Enhancing Supply Chain and Logistics Management

The complexity of modern supply chain and logistics demands robust data integration for effective management. Data provides visibility across the entire chain, from raw material sourcing to final product delivery. Tracking inventory levels, transportation routes, and delivery schedules through data analytics helps optimize stock, reduce carrying costs, and improve delivery times. This level of transparency is vital for responding quickly to disruptions and ensuring customer satisfaction.

In a world characterized by global trade, efficient supply chain management is a competitive differentiator. Data enables organizations to identify potential risks, such as geopolitical events or natural disasters, and develop contingency plans. Furthermore, it facilitates the optimization of shipping routes and modes, contributing to cost savings and improved environmental sustainability by reducing fuel consumption and emissions.

Data for Workforce, Automation, and Innovation

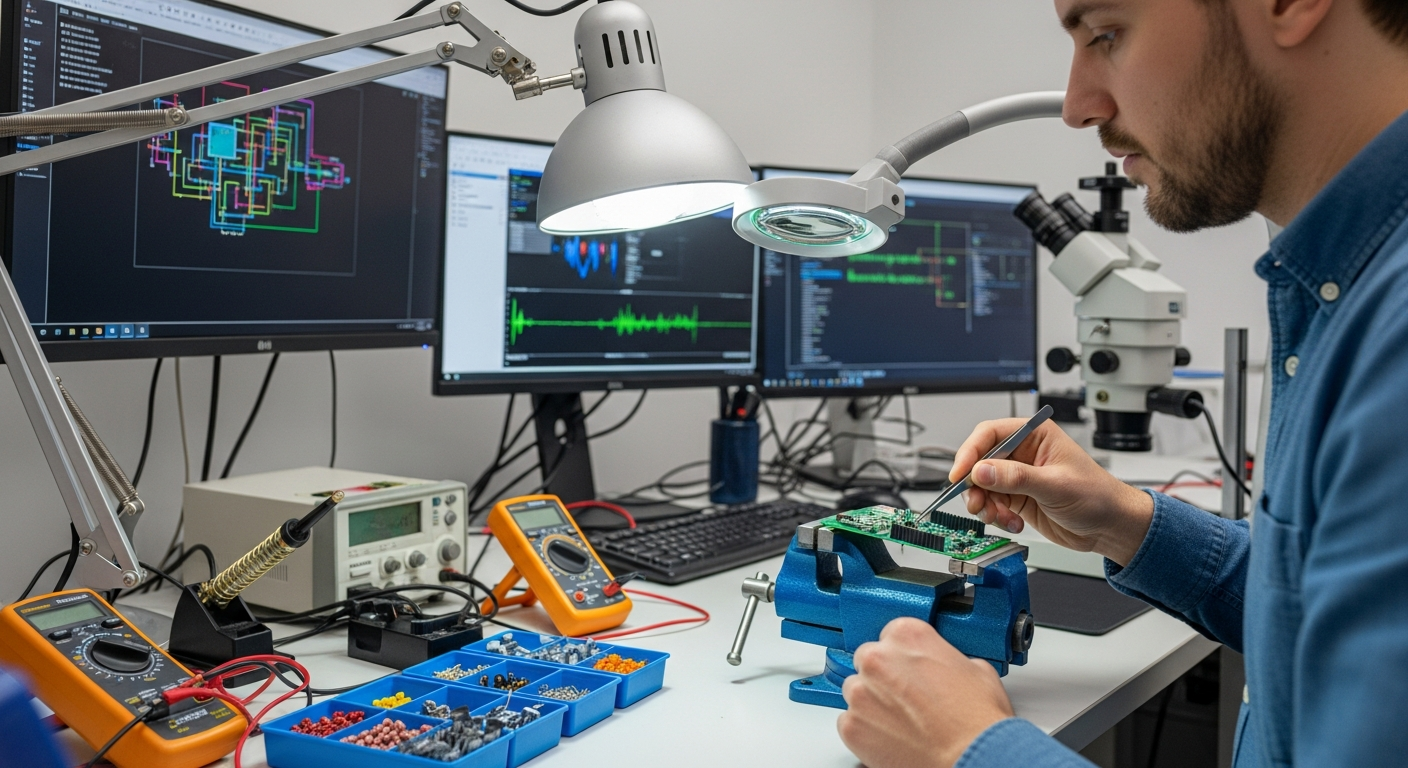

Data insights are increasingly valuable for workforce management, especially with the rise of automation and new technology. Analyzing workforce data can help identify skill gaps, optimize training programs, and enhance employee productivity and safety. For instance, data from wearable sensors can monitor worker conditions in hazardous environments, ensuring timely interventions and improving safety protocols.

Moreover, data fuels innovation by providing empirical evidence for research and development efforts. Companies can leverage market data to understand consumer preferences and emerging trends, guiding the development of new products and services. The integration of automation technologies, such as robotics and AI, relies heavily on data collection and analysis to perform tasks efficiently and adapt to changing requirements, fostering a culture of continuous improvement and technological advancement.

Digitalization for Enterprise Growth and Market Strategy

Digitalization is transforming every aspect of the enterprise, with data at its core. Businesses use data to formulate effective market strategies, understand customer behavior, and identify new avenues for growth. Analyzing sales data, customer feedback, and commerce trends allows companies to tailor their products and services, personalize marketing campaigns, and enhance the customer experience. This data-driven approach supports strategic development and market expansion.

For enterprise-level decision-making, data provides a comprehensive overview of financial performance, operational efficiency, and competitive positioning. This enables leaders to make informed choices regarding investments, mergers, and acquisitions, driving sustainable growth. By continuously monitoring market dynamics through data analytics, businesses can adapt their strategies to stay relevant and competitive in an ever-changing economic landscape.

Data for Sustainability and Future Industrial Management

Data is instrumental in advancing sustainability initiatives within industrial management. By monitoring energy consumption, waste generation, and emissions, organizations can identify areas for improvement and implement greener practices. This not only contributes to environmental protection but can also lead to significant cost savings through optimized resource use and compliance with environmental regulations.

Looking ahead, the role of data in industrial management will only expand. As industries embrace advanced technology like the Internet of Things (IoT), artificial intelligence, and machine learning, the volume and complexity of data will grow exponentially. Effective data management and analytics will be crucial for navigating future challenges, fostering continued innovation, and building resilient, sustainable industrial ecosystems capable of thriving in a dynamic global trade environment.

The strategic application of data across industrial sectors offers a clear pathway to enhanced efficiency, informed decision-making, and sustainable growth. As technology continues to evolve, the ability to collect, analyze, and act upon data will remain a critical differentiator for businesses seeking to optimize their operations and secure their future in a competitive global market.